Purpose Built for

Performance and Longevity

Applications Include:

- Wire harness manufacturing

- Cable assembly

- Electrical termination

- OEM and aftermarket wire harness programs

Support Options:

- Typical 3–4 week turnaround

- Stocking agreements for same-day / next-day shipment

- Reverse-engineered replacement tooling available

- Legacy tooling reproduction

In addition, we build custom dies, perishable tooling, die set replacements, low volume OEM wire crimping samples and crimping applicators, hand tools and hydraulic tools engineered for durability, accuracy, and consistency. We design every component to withstand heavy production loads and deliver consistent performance that you can count on.

Reliable Turnaround: Typically three-to-four-week lead times, used consistently across all tooling and machining services.

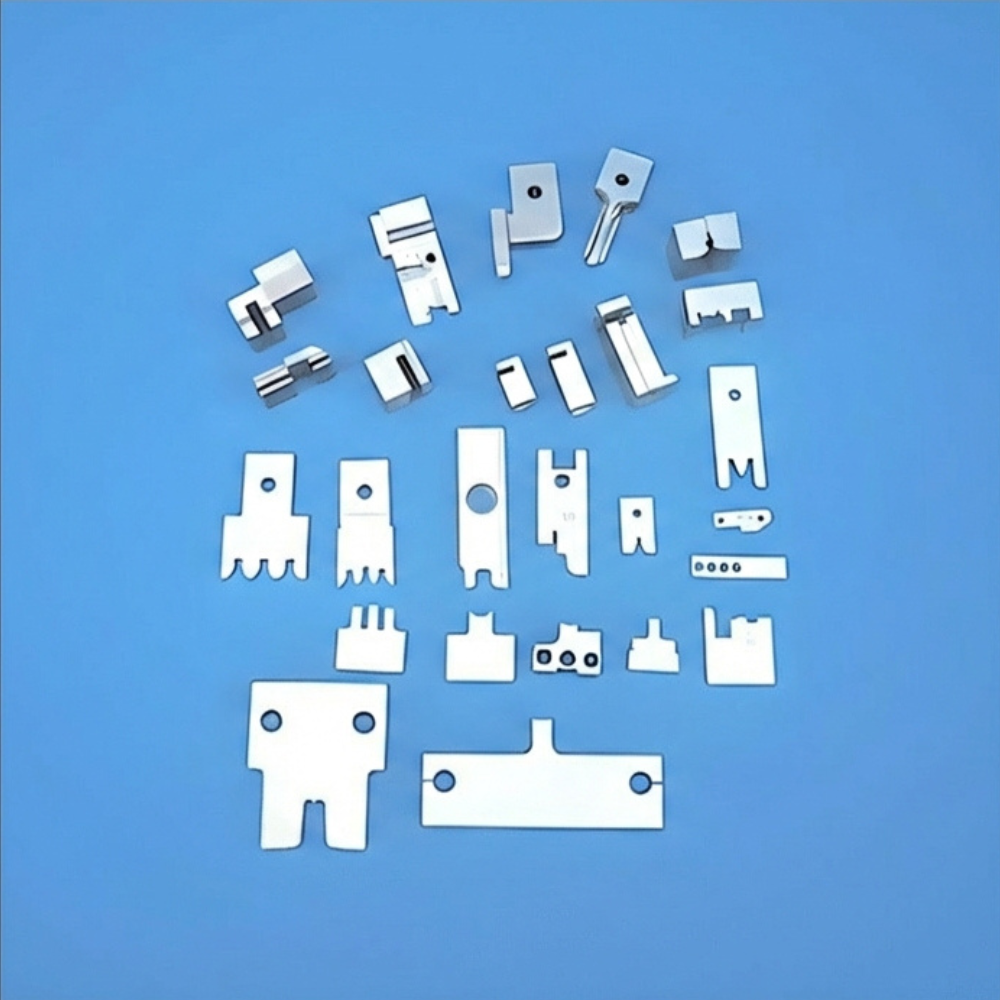

Perishable Tooling – High-Volume Replacement Tooling You Can Depend On

Perishable tooling is where manufacturing uptime is won or lost. Diamond Die engineers and manufactures high-precision replacement tooling designed for reliability, consistency, and fast turnaround, helping manufacturers keep production stable and predictable.

Typical applications include:

- Wire harness manufacturing

- Cable assembly

- Electrical termination

- OEM and aftermarket wire harness programs

Support options include:

- Typically 3-4 week turnaround

- Stocking agreements with same-day / next-day shipment

- OEM-level tolerances or better

- Reverse-engineered replacement tooling when no prints exist

- Legacy tooling reproduction

- Fast response and direct communication