Fast, Custom Tooling

Built for Precision

Not Sure Where to Start?

Find the Right Solution

Replace Worn Tooling Fast

Your line is down or parts are nearing end of life and you need perishable tooling quickly.

Set Up or Upgrade Applicators

You’re adding new terminals, changing programs, or updating existing lines and need the right applicators.

Support a New Harness Program

You need custom dies, prototype tooling, or precision machined components for a new build.

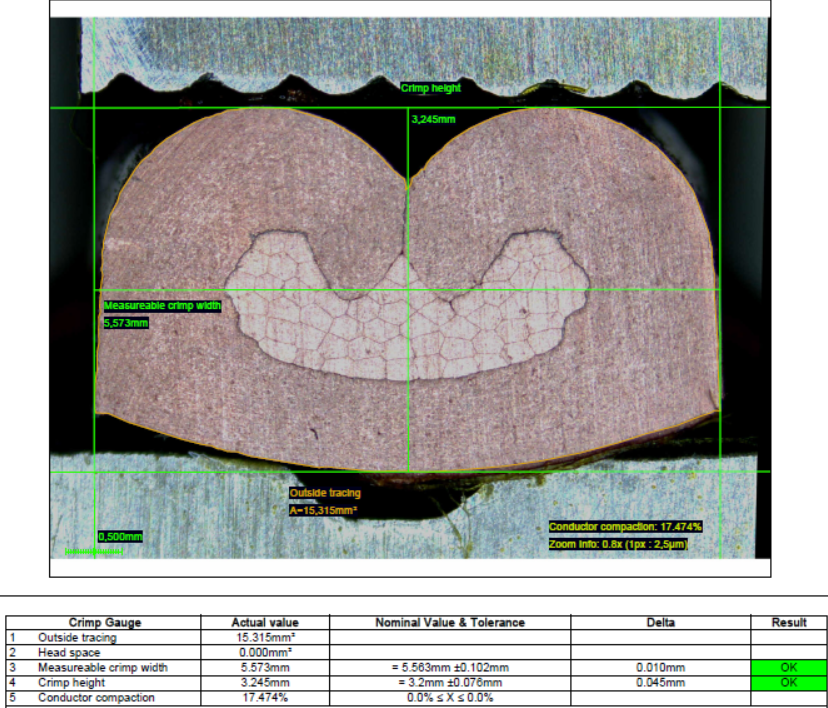

Evaluate Crimp Quality

You want cross-section analysis to validate or improve crimp integrity.

Reverse Engineer Legacy or Undocumented Tooling

You have tools in service without drawings or prints and need reliable replacements.

Perishable Tooling – Fast, Accurate, Built for High-Volume Replacement

Perishable tooling is where Diamond Die delivers some of its greatest value. We engineer and manufacture high-precision tooling designed for repeat replacement in demanding wire harness, cable assembly, and electrical termination environments. Doing so ensures consistent quality, reduced downtime, and predictable performance across every production run.

Key advantages include:

- Fast replacement lead times – typically 3-4 weeks

- Stocking agreements available for same-day or next-day shipment

- Built to OEM tolerances or better

- Long-life tooling designed for extended replacement cycles

Custom Tooling

That Fits Your Process

In addition to high-volume perishable tooling, Diamond Die also engineers and manufactures custom tooling built specifically for your application and production needs. We understand that many manufacturers can’t wait weeks for replacement tooling, and we can take that extra step. For qualifying customers, we offer stocking agreements where we build and hold inventory of your custom applicator components, tool and die components, or wire terminal perishable crimping tools. This ensures quick access to high-precision, long-lasting tooling that keeps your production moving and your operations protected from downtime.

Reliable Turnaround: Typically three to four week lead times, used consistently across all tooling and machining services.

Key Benefits:

- Next day delivery if in a stocking agreement

- Typically Three-to-four-week turnaround time

- Designed for your exact application

- Long-lasting tooling for high-volume production

- Precision you can depend on

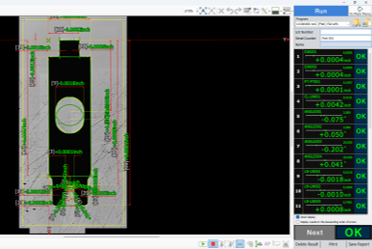

Precision Machining That Keeps Your Line Running

Our vertically integrated shop handles everything in-house, allowing for tighter quality control, faster delivery, and unmatched consistency across every component.

Capabilities include:

- Wire EDM

- Precision Surface and Blanchard grinding

- Small run prototypes

- Reverse engineering

- Cross sectional analysis

- Milling

- Laser etching

- Polishing

- Heat treating

- Small batch black oxide

Crimp Quality You Can Trust

Our Terminal Crimp Cross Section Analysis System provides the precision insights manufacturers need to reduce defects, improve safety, and ensure compliance across industries including electrical wire harness design, EV, aerospace, medical, and automotive.

Trusted by Industry Leaders

We support a wide range of manufacturers, including major OEMs, terminal producers, and cable harness manufacturers looking for dependable tooling partners and solutions built for demanding production environments.