Fine Wire EDM Machining for Prototyping

When traditional machining methods fall short, fine wire EDM machining delivers unmatched precision for prototyping intricate and high-tolerance components. Using a wire electrical discharge machine, this process relies on controlled electrical spark erosion to remove material from conductive metals without applying mechanical force.

The work piece is submerged in deionized water, which acts as a dielectric and coolant while maintaining a consistent spark gap. The result is clean, burr-free edges and highly detailed prototype parts.

Ideal for small parts, tool and die components, and electric vehicle applications, wire EDM prototype machining offers cost-effective, repeatable solutions for even the most demanding geometries.

Wire EDM Manufacturing & Reverse Engineering Capabilities

At Diamond Die, our advanced wire EDM capabilities support both original manufacturing and precision reverse engineering. Our Clinton Township machine shop is equipped with state-of-the-art wire electrical discharge machines, enabling us to produce highly accurate machined parts with complex geometries and tight tolerances.

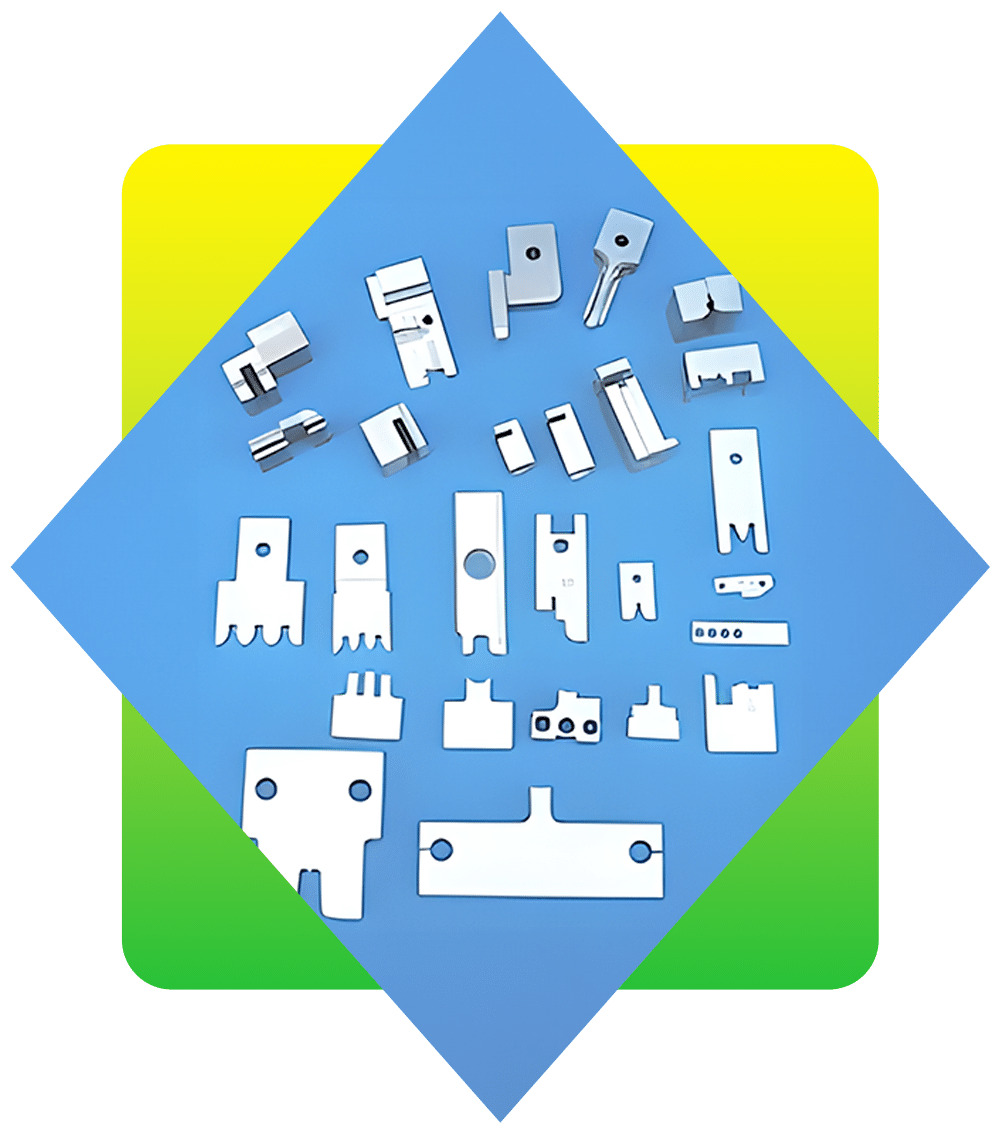

We manufacture tool and die components, including crimping applicators and press tooling for wire termination, using fine wire EDM to achieve precise cuts and intricate internal features that traditional machining methods cannot match.

Reverse engineering is a cornerstone of our operation. Whether recreating discontinued parts or replicating components for system integration, we use a combination of high-resolution digital imaging, optical comparators, and EDM-based measurement techniques.

Our process ensures that every replicated part meets original specifications, including spark gap tolerances and electrode profiles. From hole drilling EDM to prototype tooling development, we deliver refined, reliable results that are very detailed, shaped by tool electrode erosion, and engineered for performance-critical applications.

Wire EDM FAQs

Because the process relies on electrical discharge rather than mechanical force, it can machine extremely hard or brittle materials without introducing stress, deformation, or tool wear. We often work with advanced alloys and hardened metals used in automotive, aerospace, medical, and EV component manufacturing.

The result is a cleaner, more accurate part with tighter internal radii and burr-free edges. Wire EDM is especially beneficial for small parts, fine details, and areas that require precision hole drilling or tight corner radii.

This is especially valuable for industries such as automotive, medical, and EV manufacturing, where validation of performance-critical parts, like crimping dies or mold inserts, is required before full-scale production.

When voltage is applied, electrical charges jump across the spark gap, vaporizing small amounts of material at thousands of spark discharges per second. The result is a series of precise cuts without physical contact, enabling high-tolerance machining of complex or hardened parts.

Upgrade Your Production Line With Precision Wire EDM Tooling Solutions

Enhance your manufacturing process with precision-crafted perishable tooling produced through advanced wire EDM machining. We leverage high-accuracy electrical discharge machining (EDM) to deliver perishable die tools, custom crimping applicators, and tool and die components with precise cuts and exceptional surface finishes.

From hole drilling EDM to complete die assemblies, we create machined parts that reduce wear, improve efficiency, and integrate seamlessly into your production line. This approach not only reduces downtime but also supports long-term cost-effectiveness through minimal tooling degradation.