Unmatched Perishable Crimping Tooling and Precision Parts in Clinton Township, MI

Along with world-class materials, we prioritize speed at Diamond Die. Our quick turnaround times are testimony to our commitment to our customers’ time and needs. Our perishable tooling parts are crafted from the finest steel, ensuring durability, reliability, and consistency—a trifecta of benefits that are hard to find in the industry. By choosing Diamond Die, you are choosing the best for your business.

Manufacturing and Reverse Engineering Capabilities

Step into a world of innovation at our top-tier machine shop. With state-of-the-art equipment and dedicated personnel, Diamond Die offers comprehensive manufacturing capabilities, including die tooling machining services and the production of tool and die equipment products such as crimp presses for wire termination and custom crimping applicators.

More than just a provider of tooling parts, we also excel in reverse engineering. Our team can perfectly reproduce any component—whether for a simple part replacement or an entirely new production line. We utilize equipment like a digital optical comparator, high resolution camera and other techniques to ensure the highest accuracy in our reproductions for your critical components. Our expertise extends to prototype tooling development, allowing you to test and refine your designs before full-scale production.

Perishable Tooling FAQs

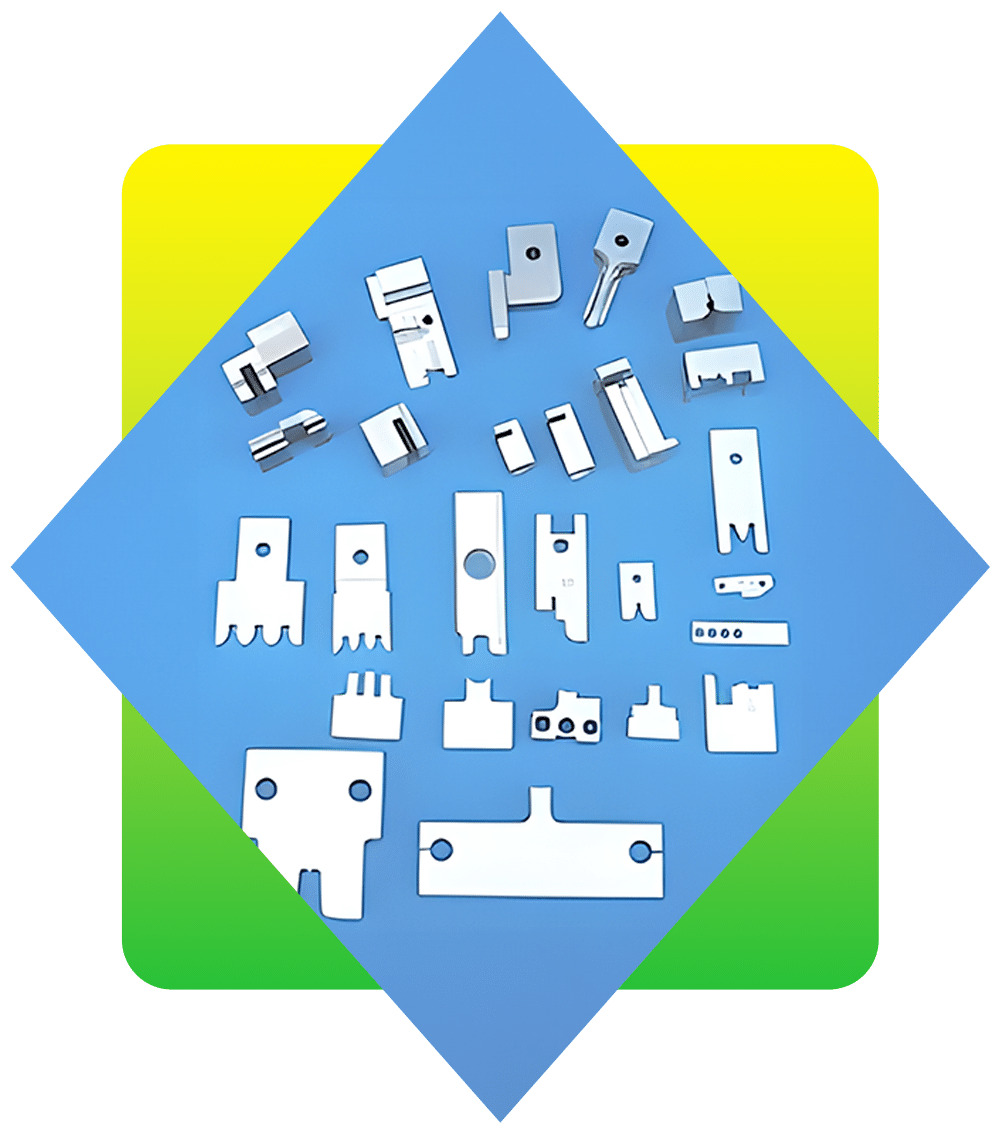

Examples include tools and dies used in wire processing, such as those for cutting, bending, and forming wire terminals into intricate shapes. Perishable tools directly impact manufacturing processes by influencing factors like production speed, tight tolerances, and quality control.

- Tooling designed specifically for your application.

- Materials like A2 and S7 offer durability and resistance to wear and tear.

- State-of-the-art manufacturing techniques like CNC machining for precision and efficiency.

- Highly skilled manufacturers with expertise in tooling for wire processing, such as us at Diamond Die and Mold.

- Proper maintenance and regular inspections.

- Implementing robust quality control measures throughout the manufacturing process.

- Partnering with a reputable supplier with a proven track record of delivering high-quality perishable tooling.

- Utilizing cost-saving strategies by optimizing tool designs and selecting appropriate materials.

Upgrade Your Production Line With Our Perishable Tooling Solutions

Upgrade your assembly line with our diverse range of perishable tooling and expertly crafted dies for both standard and extraordinary applications. Benefit from our in-house die tooling services for low-volume crimp projects, enjoying the same precision and quality that our high-volume clients experience.

We offer a wide array of perishable tooling for manufacturing, including high-quality perishable tooling, perishable die tools, and crimping tools and applicators. Our expertise extends to tooling for die and mold creation, with a focus on precision die tooling for various industries, including die tooling for electric vehicles.

Allow us to support and streamline your operations by facilitating seamless workflows and reducing downtime.