Benefits of Diamond Die & Mold’s Braiding & Shielding Crimp Tools

When it comes to braiding crimps and shielding crimps, Diamond Die and Mold’s tools stand out for their durability and adaptability. Here are some of the key benefits our crimping tools offer:

These advantages make our tools ideal for use in sectors that rely on uninterrupted data flow and high-voltage cable management, including aerospace, telecommunications, and automotive industries.

Advanced Crimping Process for High-Voltage Applications

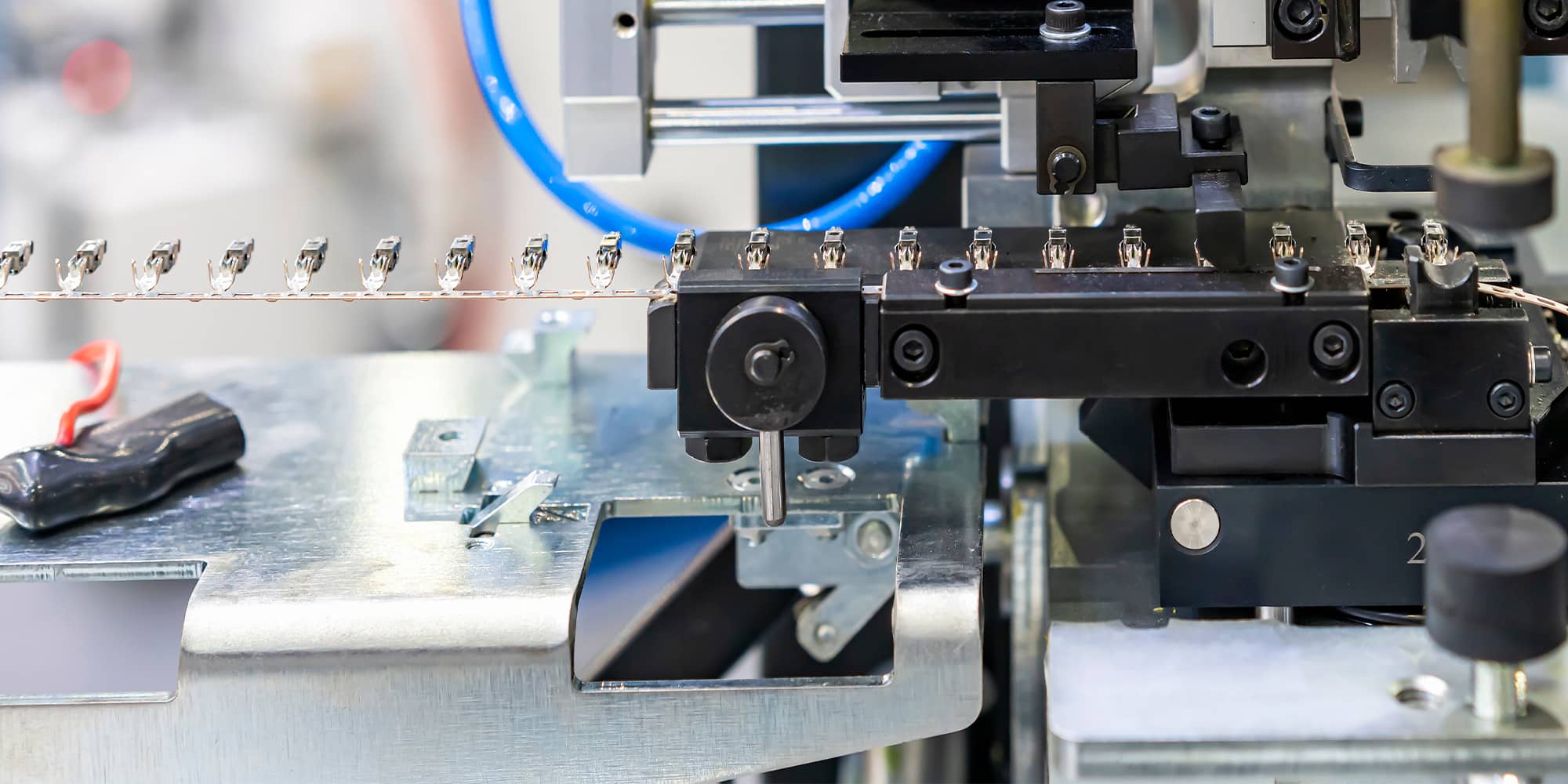

The high-voltage crimping process requires specialized equipment that meets stringent safety and quality standards. Diamond Die and Mold’s tools deliver dependable crimps for cables in high-stakes environments like electric vehicle (EV) production and power distribution systems. Our tools enable precise connections that withstand high voltage, ensuring long-lasting, dependable performance for mission-critical cables and harnesses.

Our high-voltage crimp tools are designed for efficiency and ease of use. The ergonomic design reduces operator fatigue, while the precise crimping action minimizes material waste, helping to keep production costs under control. Whether you’re crimping for shielding or braiding applications, our tools provide the accuracy and stability needed for top-quality results in high-voltage environments.

Braiding or Shielding Crimps FAQs

Choose Diamond Die & Mold for Specialized Crimping Tools in Harness Manufacturing

Harness manufacturing requires precise, secure crimps to ensure seamless performance across complex wiring systems. Diamond Die and Mold’s tools are tailored for harness manufacturing’s needs, supporting the creation of organized, efficient wiring assemblies that are resistant to wear and EMI. Our high-quality crimps allow for efficient assembly, ensuring each crimp meets safety and performance requirements.

Our harness manufacturing tools come in various configurations to suit different cable sizes and materials. This versatility enables manufacturers to create customized harnesses that meet the exact specifications of each application, whether for EV production or other high-stakes projects. Diamond Die and Mold’s crimping solutions ensure your harness assemblies meet the highest standards of reliability and performance.