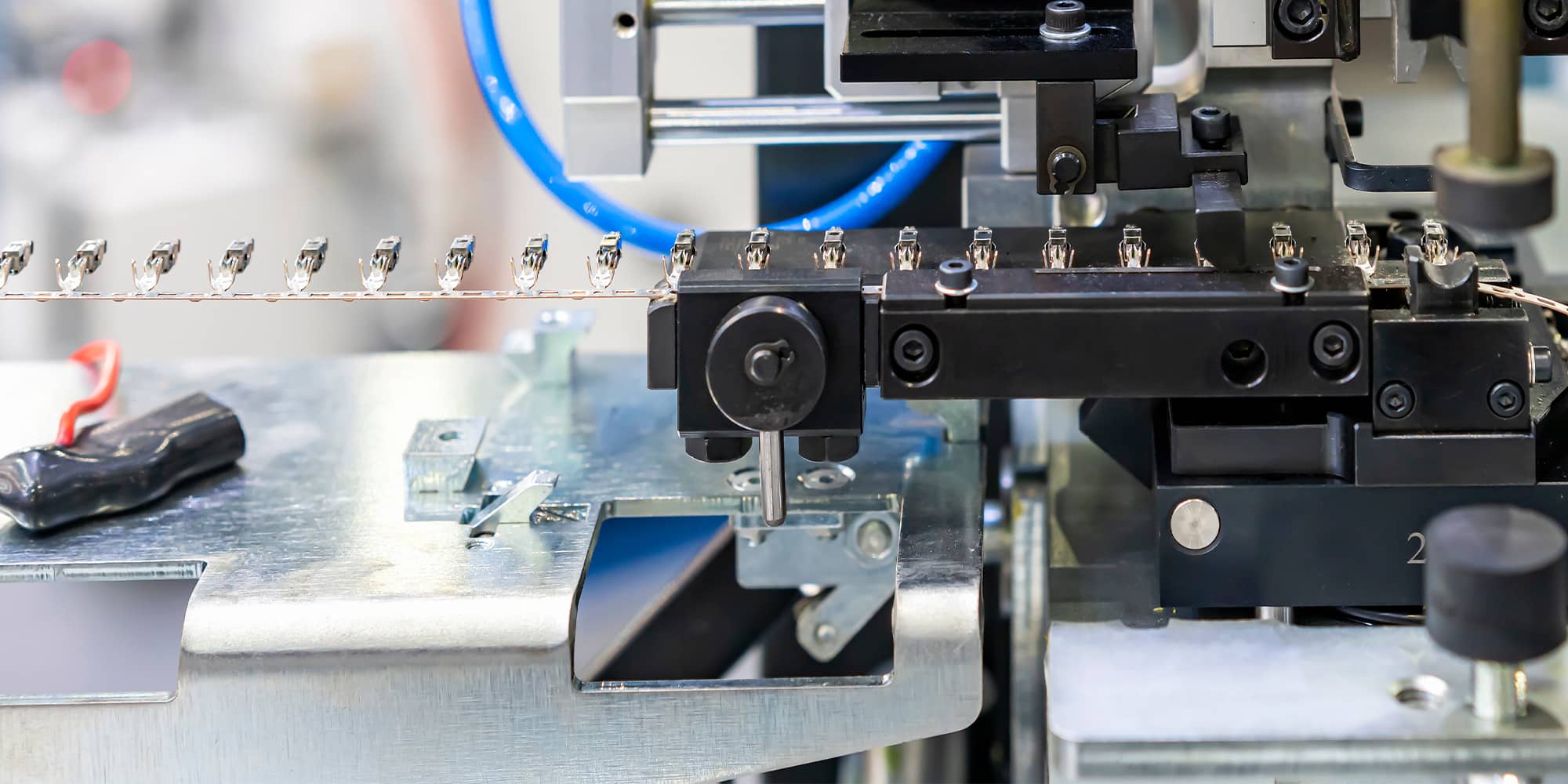

Crimp Multiple Wires

Depending on the terminal type, hydrofeed terminating applicators can tackle four wires simultaneously. This versatility makes them ideal for applications requiring multiple terminations, as they adapt to varying wire sizes and terminal configurations. Their larger opening ensures smooth handling of complex crimping tasks, offering reliable performance across different termination needs.

If you want to know if your terminal setups can crimp four wires at once using our hyrdofeed terminating applicators, contact our team today!

What Is a Hydrofeed Terminating Applicator?

A hydrofeed termination applicator is a specialized tool designed for efficient and flexible wire termination in mid-sized industrial applications. It features an adjustable feed system that allows operators to perform single or multiple terminations simultaneously, with the capacity to handle up to four terminations at once, depending on the size of the wire and terminals being used. This adaptability makes the hydrofeed ideal for various manufacturing processes, where precise and efficient terminations are critical.

Hi-Speed applicators are built to handle high-volume signal-level terminals. They come with multiple feed guide options, including left to right, right to left, and end to end, making them compatible with most presses used in wire termination.

On the other hand, hydrofeed applicators are ideal for mid-size termination tasks, with or without an adjustable feed system. They can handle single or multiple terminations (up to four) and various wire sizes and terminal types. Their larger opening compared to Hi-Speed applicators allows for more flexibility, making them suitable for customized tasks in industries like automotive, aerospace, and electronics.

Hydrofeed Terminating Applicator FAQs

This tool can be used in various applications, such as crimping terminals on wire conductors for wire harnesses in the automotive, aerospace, and electronics industries. The hydrofeed provides a reliable, high-quality solution for terminating wires and ensuring secure connections in electrical systems.

Whether you’re dealing with low- or high-voltage systems, hydrofeed’s ability to manage multiple terminations at once improves productivity and ensures consistent, high-quality results.

Its versatility and adaptability make it ideal for industries that require precision and flexibility when dealing with complex electrical wiring setups.

This flexibility is particularly useful in industries like automotive or aerospace, where various wire sizes are often needed for different parts of a wire harness or electrical system. The adjustable system allows for consistent, high-quality terminations, regardless of the wire or terminal size.

Whether dealing with standard or high-voltage systems, the hydro feed’s precision and adaptability ensure high-quality terminations for even the most complex projects.

The hydrofeed’s ability to handle mid-sized cable termination projects, including high-voltage applications, makes it a valuable tool for ensuring secure, high-quality terminations. Its adaptability, combined with its efficiency in cable termination and crimping tasks, makes it indispensable in industries that demand reliable and durable electrical connections.

Contact Diamond Dies & Mold for a Hydrofeed Terminating Applicator

Diamond Die and Mold (DDM) has been a leader in precision tooling and machining since 1956. Our hydrofeed (medium-duty) applicators are built for mid-sized termination tasks, handling up to four terminations at once with an adjustable feed system.

As an ISO 9001:2015 certified, woman-owned business, we ensure top-quality products through CAD/CAM design, reverse engineering, and 100% inspection. Contact us today for custom solutions.