Features of Our Heavy Duty Dies

Benefits of Using Our Heavy Duty Dies

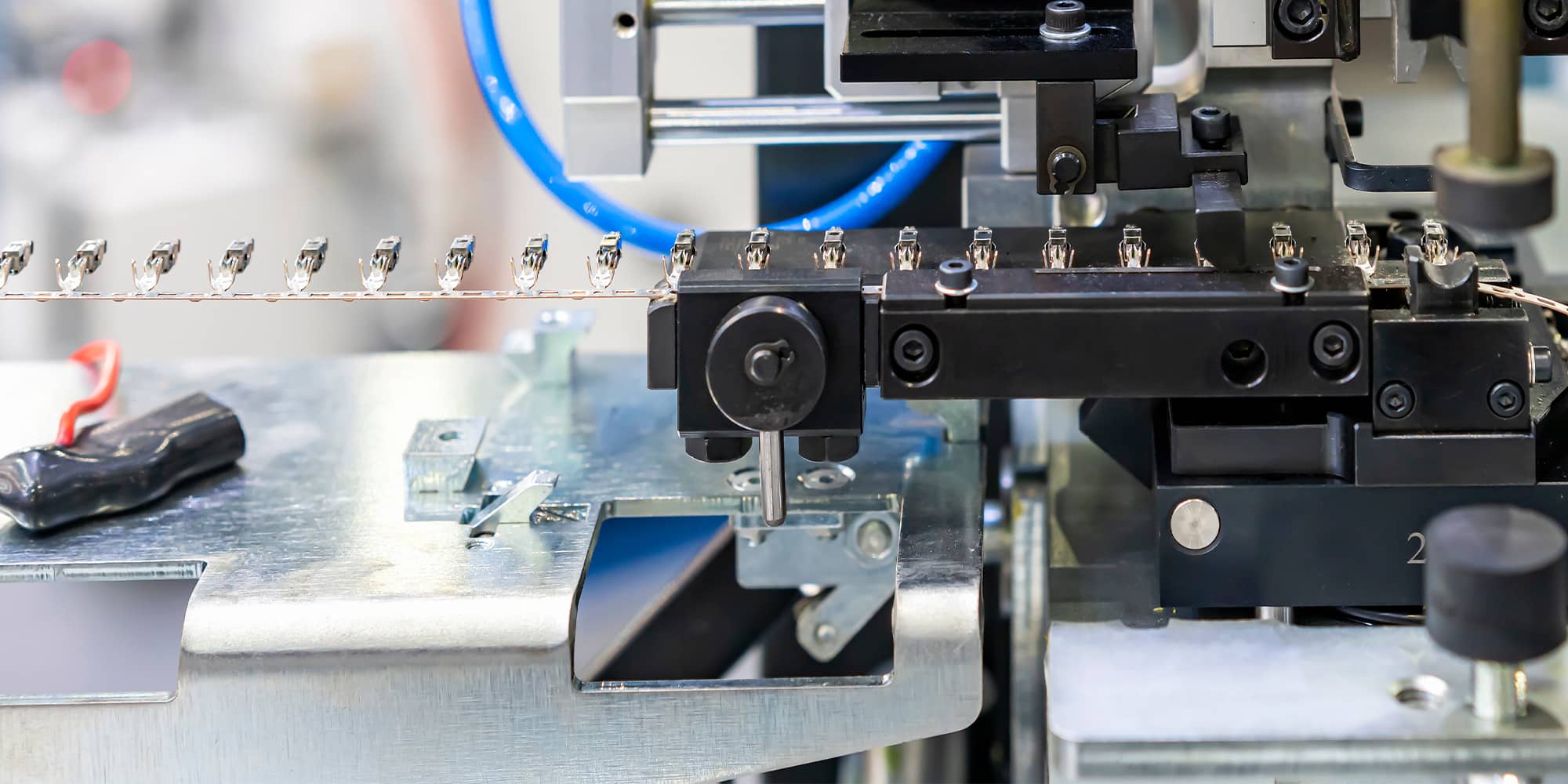

Our heavy duty dies are the right choice for high-voltage and conventional battery cables in electric vehicles. Their robust construction and innovative design ensure they can handle the demands of modern electric vehicle manufacturing, providing reliable and efficient wire terminating solutions.

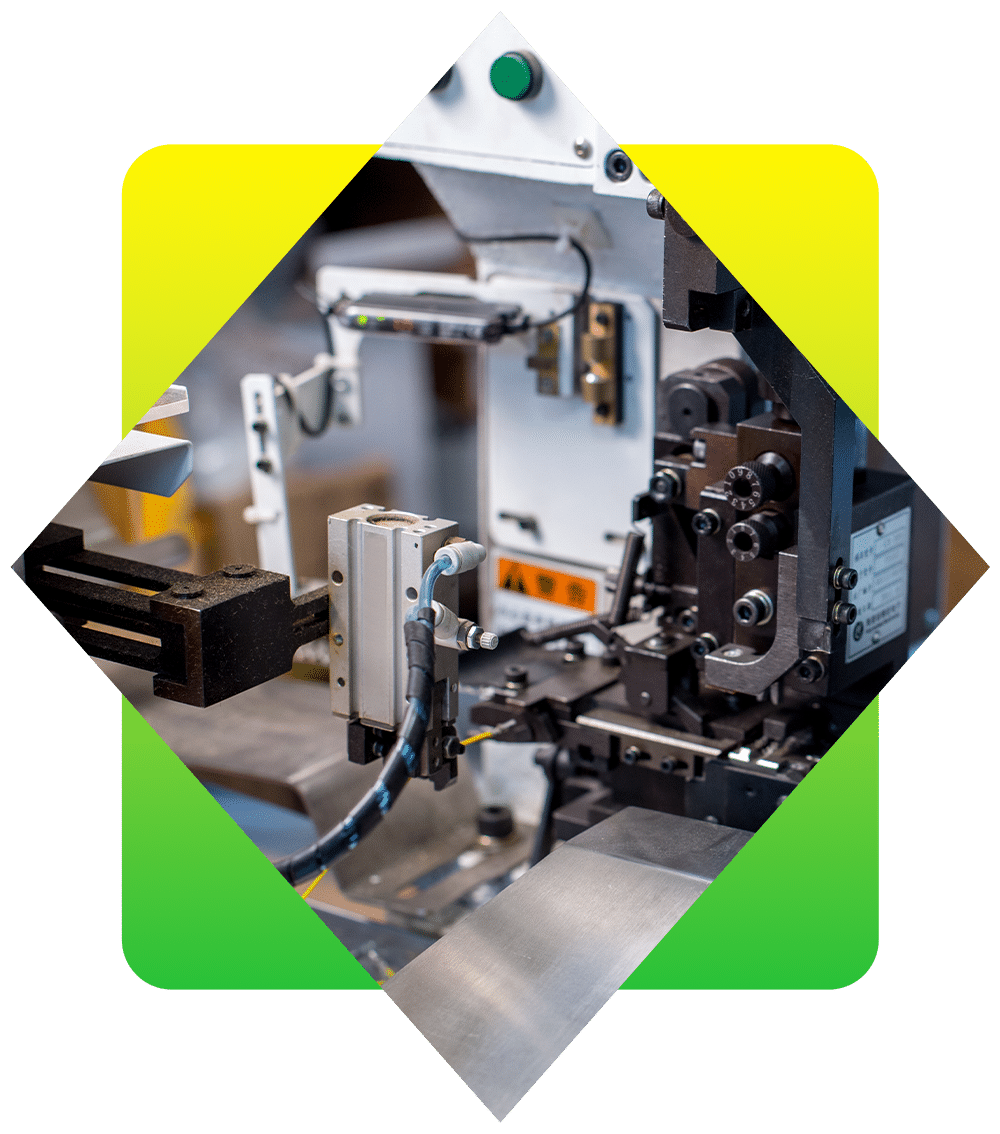

The single-piece shuttle design not only simplifies the loading and unloading process but also makes maintenance easier. Operators can quickly perform routine maintenance tasks, reducing downtime and ensuring continuous operation. This design also facilitates quick troubleshooting and repairs, keeping your production line running smoothly.

By incorporating a pneumatically-driven feed guide system, our heavy duty dies enhance efficiency and productivity. This system allows for precise and consistent terminal feeding, reducing errors and improving overall production speed. The versatility of the feed guide system also means that you can easily switch between different feeding directions without extensive reconfiguration.

Frequently Asked Questions About Heavy Duty Dies

Contact Diamond Die in the Midwest for Heavy Duty Dies

For more information about our heavy duty dies, die sets, and die applicators, and how they can benefit your wire terminating processes, contact Diamond Die today. Our experts are ready to assist you with your specific needs and provide the best solutions for your industrial applications.